The world of chemical fibers relies heavily on specialized adhesives and support systems to ensure durability, performance, and structural integrity across countless applications.

🔬 Understanding the Chemistry Behind Fiber Adhesion

Chemical fibers, also known as synthetic or man-made fibers, require unique bonding solutions that differ significantly from natural fiber treatments. These materials, including polyester, nylon, acrylic, and aramid fibers, possess distinct surface characteristics that influence how adhesives interact with them. The molecular structure of synthetic fibers typically features smooth, non-porous surfaces with low surface energy, making traditional adhesive bonding challenging without proper surface preparation or specialized formulations.

Modern adhesive technology has evolved to address these challenges through innovative chemical compositions. Polymer-based adhesives, epoxy resins, cyanoacrylates, and polyurethane systems have become the backbone of fiber bonding applications. Each adhesive type offers unique advantages depending on the specific fiber composition, intended application environment, and performance requirements.

🧪 Types of Adhesives for Chemical Fiber Applications

Epoxy-Based Adhesive Systems

Epoxy adhesives represent one of the most versatile and reliable options for bonding chemical fibers. These two-component systems create exceptionally strong bonds through a curing process that forms crosslinked polymer networks. The chemical reaction between resin and hardener generates adhesive joints that resist moisture, chemicals, and temperature fluctuations effectively.

For composite materials incorporating carbon fibers or glass fibers, epoxy adhesives provide superior mechanical properties and excellent fatigue resistance. Manufacturing sectors such as aerospace, automotive, and sporting goods industries extensively use epoxy systems for their ability to distribute stress evenly across bonded surfaces while maintaining lightweight characteristics.

Polyurethane Bonding Solutions

Polyurethane adhesives offer remarkable flexibility and elasticity, making them ideal for applications where chemical fibers experience dynamic loading or movement. These adhesives cure through moisture-activated chemical reactions, forming bonds that accommodate thermal expansion and contraction without compromising structural integrity.

The textile industry frequently employs polyurethane adhesives for laminating fabrics, attaching decorative elements, and creating composite structures. Their resistance to dry cleaning solvents and washing cycles makes them particularly valuable for apparel and upholstery applications involving synthetic fibers.

Cyanoacrylate Instant Adhesives

Commonly known as super glues, cyanoacrylates provide rapid bonding solutions for chemical fibers when speed is essential. These adhesives polymerize almost instantaneously upon contact with moisture, creating strong bonds within seconds. However, their brittleness and sensitivity to impact limit their use in applications requiring flexibility or shock absorption.

Precision manufacturing and small-scale repairs often utilize cyanoacrylate adhesives for their convenience and speed. Modified formulations with enhanced toughness and gap-filling properties have expanded their applicability in fiber reinforcement projects.

🏗️ Support Systems and Reinforcement Strategies

Beyond adhesives alone, comprehensive support systems play crucial roles in maximizing the performance of chemical fiber applications. These systems integrate structural reinforcements, surface treatments, and mechanical fastening methods to create robust assemblies that withstand demanding operational conditions.

Matrix Systems for Fiber Composites

In composite manufacturing, the matrix system serves as both adhesive and support structure, embedding fibers within a continuous phase that transfers loads and protects individual filaments. Thermoset resins such as epoxy, polyester, and vinyl ester create permanent matrix structures through irreversible curing reactions, while thermoplastic matrices offer recyclability and reformability advantages.

The selection of appropriate matrix materials depends on multiple factors including operating temperature ranges, chemical exposure environments, and mechanical performance requirements. Aerospace applications typically demand high-performance epoxy matrices, whereas automotive components might utilize more cost-effective polyester systems.

Surface Treatment Technologies

Effective adhesion to chemical fibers often requires surface modification to increase surface energy and promote chemical bonding. Plasma treatment, corona discharge, flame treatment, and chemical etching represent common surface preparation methods that enhance wettability and create reactive sites for adhesive attachment.

These treatments temporarily alter the fiber surface chemistry, introducing polar functional groups that improve adhesive compatibility. Manufacturers must carefully control treatment parameters to achieve optimal results without damaging fiber properties or introducing defects that could compromise performance.

⚙️ Application Methods and Best Practices

Preparation and Environmental Control

Successful adhesive bonding begins with meticulous preparation and environmental management. Chemical fibers must be thoroughly cleaned to remove contaminants such as processing oils, mold release agents, and atmospheric particles that interfere with adhesion. Solvent cleaning, ultrasonic cleaning, or vapor degreasing techniques ensure pristine surfaces ready for bonding.

Temperature and humidity control during application and curing significantly impact adhesive performance. Most adhesive systems specify optimal environmental conditions within narrow ranges. Deviations from recommended parameters can result in incomplete curing, reduced bond strength, or premature failure under service conditions.

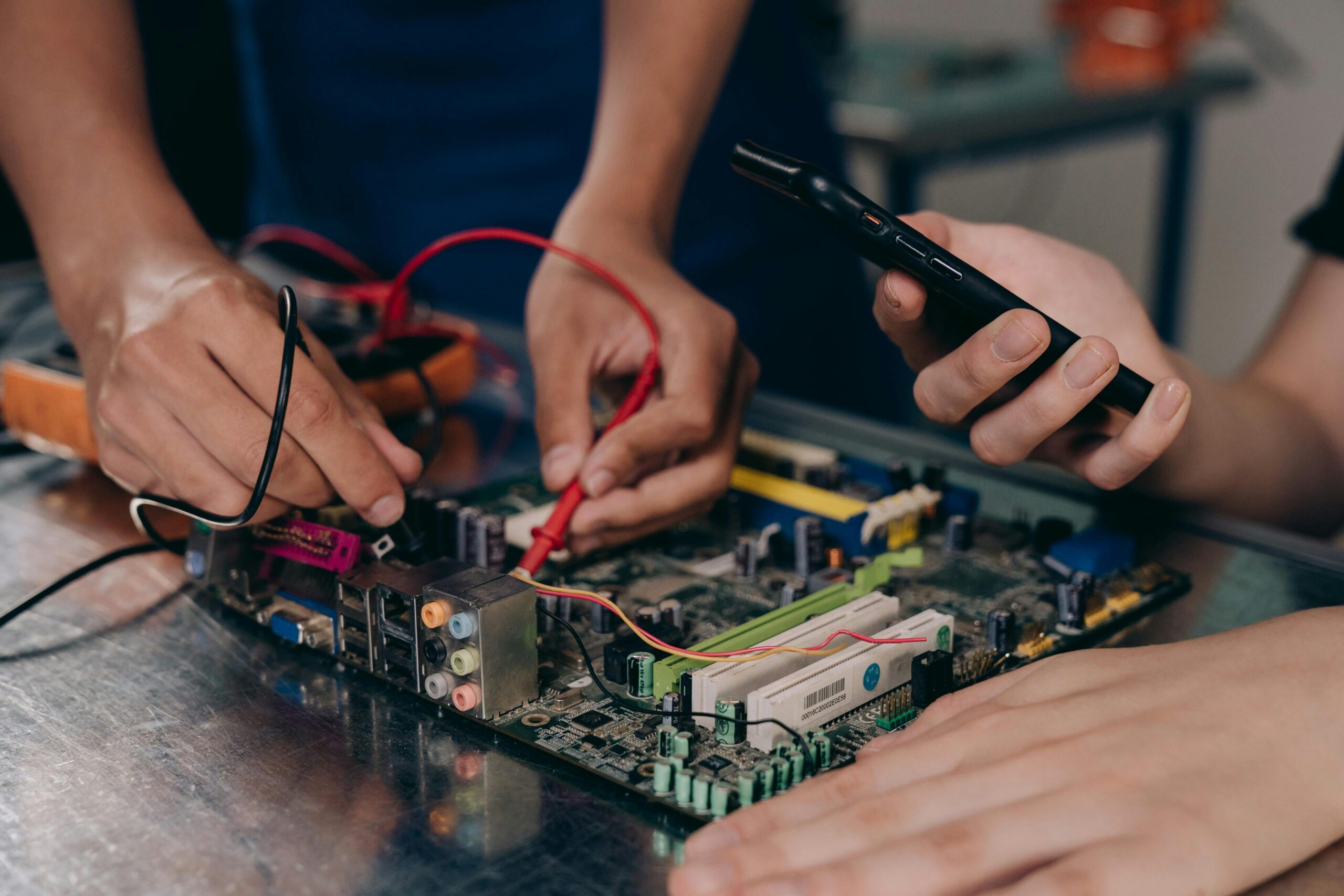

Dispensing and Application Techniques

Modern manufacturing facilities employ sophisticated dispensing equipment to ensure consistent adhesive application. Automated systems provide precise control over bead geometry, placement accuracy, and material volume, eliminating human variability and improving production efficiency.

- Manual application with syringes or applicators for low-volume or repair operations

- Robotic dispensing systems for high-volume production with complex geometries

- Spray application for large surface areas requiring thin, uniform coverage

- Roll coating for continuous web processing of textile materials

- Dip coating for three-dimensional components requiring complete coverage

🎯 Industry-Specific Applications and Requirements

Aerospace and Aviation Sector

The aerospace industry maintains the most stringent requirements for adhesive bonding of chemical fibers. Carbon fiber reinforced polymers (CFRP) dominate modern aircraft structures, requiring adhesive systems that meet rigorous certification standards for strength, durability, and fire resistance. Structural adhesives in these applications must demonstrate consistent performance across extreme temperature ranges from -55°C to +120°C while resisting aviation fuels, hydraulic fluids, and atmospheric conditions at altitude.

Quality control procedures include non-destructive testing methods to verify bond integrity without compromising structural components. Ultrasonic inspection, thermography, and radiographic techniques detect voids, delaminations, or insufficient adhesive coverage that could lead to catastrophic failures.

Automotive Manufacturing

Automotive applications increasingly incorporate chemical fibers for weight reduction and improved fuel efficiency. Adhesive bonding enables the joining of dissimilar materials such as carbon fiber composites to aluminum or steel structures, creating hybrid assemblies that optimize strength-to-weight ratios.

Crash energy management represents a critical consideration in automotive adhesive selection. Adhesives must absorb impact energy while maintaining passenger compartment integrity during collisions. Toughened epoxy and polyurethane systems with controlled failure modes provide predictable performance during crash events.

Textile and Apparel Industry

The fashion and textile sectors utilize adhesives for laminating fabrics, attaching functional membranes, and creating decorative elements on garments manufactured from chemical fibers. Flexibility, washability, and comfort remain paramount concerns alongside adequate bond strength.

Hot melt adhesives, polyurethane films, and solvent-based systems each serve specific niches within textile manufacturing. Environmental regulations increasingly drive the adoption of water-based and solventless adhesive technologies that reduce volatile organic compound emissions while maintaining performance standards.

🔍 Quality Assurance and Testing Protocols

Ensuring reliable adhesive bonds requires comprehensive testing programs that evaluate performance under simulated service conditions. Standardized test methods provide objective measurements of bond strength, durability, and failure modes that inform design decisions and quality control procedures.

Mechanical Testing Methods

Tensile testing, lap shear testing, and peel testing represent fundamental mechanical evaluations for adhesive bonds. These tests measure the forces required to separate bonded assemblies under controlled loading conditions, providing data for structural calculations and safety factor determinations.

Advanced testing protocols simulate complex loading scenarios including fatigue cycling, impact resistance, and creep behavior under sustained loads. Long-term durability assessments subject bonded samples to accelerated aging conditions involving elevated temperatures, humidity exposure, and chemical immersion to predict service life expectations.

Environmental Exposure Testing

Chemical fibers and their adhesive bonds must withstand diverse environmental challenges throughout their service life. Salt spray testing evaluates corrosion resistance for marine applications, while thermal cycling verifies performance across temperature extremes. UV exposure chambers assess degradation from sunlight for outdoor applications, and chemical resistance testing confirms compatibility with anticipated contaminants.

💡 Innovations and Future Developments

Research laboratories and material science companies continuously develop next-generation adhesive technologies that address emerging challenges in chemical fiber applications. Smart adhesives incorporating self-healing capabilities represent one promising direction, utilizing microencapsulated healing agents that automatically repair microscopic damage before it propagates into catastrophic failures.

Nanotechnology integration enhances adhesive performance through reinforcing nanoparticles that improve mechanical properties, thermal conductivity, and electrical characteristics. Carbon nanotubes, graphene platelets, and nanosilica particles create multifunctional adhesive systems with unprecedented capabilities.

Bio-based adhesives derived from renewable resources offer sustainable alternatives to petroleum-derived systems. Soy proteins, lignin derivatives, and cellulose-based formulations provide environmentally responsible bonding solutions with performance characteristics approaching traditional synthetic adhesives.

📊 Selecting the Right Adhesive System

Choosing appropriate adhesives and support systems for chemical fiber applications requires systematic evaluation of multiple factors. Material compatibility, performance requirements, manufacturing constraints, and economic considerations all influence the selection process.

| Factor | Considerations | Impact on Selection |

|---|---|---|

| Fiber Type | Polyester, nylon, aramid, carbon | Determines surface energy and chemical compatibility |

| Service Temperature | Continuous and peak exposure ranges | Defines thermal stability requirements |

| Chemical Exposure | Solvents, fuels, acids, bases | Requires resistant formulations |

| Loading Conditions | Static, dynamic, impact, fatigue | Influences adhesive toughness needs |

| Cure Requirements | Time, temperature, equipment | Affects manufacturing feasibility |

🛠️ Troubleshooting Common Bonding Challenges

Even with careful planning and execution, adhesive bonding projects occasionally encounter problems requiring systematic troubleshooting approaches. Understanding common failure modes and their root causes enables rapid problem resolution and prevents recurrence in future production.

Adhesion Failures

When bonds fail at the adhesive-substrate interface, surface contamination or inadequate surface preparation typically bears responsibility. Implementing more rigorous cleaning protocols, enhancing surface treatments, or selecting adhesives with better wetting characteristics usually resolves these issues.

Cohesive Failures

Failures within the adhesive layer itself indicate either improper mixing ratios, incomplete curing, or adhesive selection inappropriate for the loading conditions. Verifying mixing equipment calibration, extending cure times, or upgrading to higher-performance adhesive systems addresses cohesive failure problems.

🌍 Environmental and Safety Considerations

Responsible adhesive use encompasses worker safety, environmental protection, and end-of-life considerations. Modern regulations mandate reduced volatile organic compound emissions, elimination of hazardous substances, and improved recyclability of bonded assemblies.

Personal protective equipment including gloves, safety glasses, and respiratory protection prevents exposure to uncured adhesive components. Adequate ventilation systems remove vapors from work areas, maintaining air quality within occupational exposure limits. Material safety data sheets provide essential information for safe handling, storage, and emergency response procedures.

Disposal of expired adhesives and contaminated materials requires compliance with local environmental regulations. Many adhesive manufacturers offer take-back programs or provide guidance for proper waste management practices that minimize environmental impact.

🚀 Maximizing Performance Through Integrated Design

Achieving optimal results from adhesive bonding of chemical fibers requires holistic design approaches that consider the entire system rather than isolated components. Joint geometry, stress distribution, environmental protection, and manufacturing feasibility must all align to create successful products.

Finite element analysis software enables engineers to simulate stress patterns within bonded assemblies, identifying high-stress concentrations that might precipitate premature failures. Optimizing overlap lengths, incorporating stress-relief features, and selecting appropriate adhesive properties based on computational predictions improves reliability while reducing development costs.

The journey toward mastering adhesive bonding for chemical fibers combines scientific understanding, practical experience, and continuous innovation. As material technologies advance and application demands evolve, the synergy between adhesives and synthetic fibers will continue driving progress across industries from aerospace to consumer products, creating lighter, stronger, and more durable solutions for tomorrow’s challenges. ✨

Toni Santos is a preservation specialist and material conservator specializing in the restoration of botanical specimens, the stabilization of chemical fibers, and the structural analysis of degraded organic materials. Through an interdisciplinary and technically-focused approach, Toni investigates how natural and synthetic materials decay over time — and how to reverse, slow, and map these processes for cultural and scientific preservation. His work is grounded in a fascination with materials not only as physical substrates, but as carriers of environmental history. From botanical tissue restoration to fiber stabilization and decay structure mapping, Toni uncovers the chemical and biological pathways through which organic matter degrades and how intervention can preserve material integrity. With a background in conservation science and environmental material studies, Toni blends laboratory analysis with fieldwork to reveal how plants and fibers respond to environmental stressors, aging, and preservation strategies. As the creative mind behind qorvalyn, Toni curates preservation case studies, structural decay analyses, and conservation protocols that advance the technical understanding of material longevity, botanical integrity, and fiber resilience. His work is a tribute to: The recovery and stabilization of Botanical Material Restoration The chemical treatment of Chemical Fiber Preservation The mitigation strategies of Environmental Decay Reduction The diagnostic visualization of Preservation Structure Mapping Whether you're a conservation professional, material researcher, or steward of fragile collections, Toni invites you to explore the science of preservation — one fiber, one specimen, one intervention at a time.