Plasticizer loss leads to product failure, shortened lifespan, and costly replacements. Understanding early detection methods protects your investment and ensures materials perform reliably over time.

🔬 Understanding Plasticizers and Their Critical Role

Plasticizers are essential additives incorporated into polymer materials to enhance flexibility, workability, and durability. These molecules integrate between polymer chains, reducing intermolecular forces and allowing materials to bend without breaking. Common applications include flexible PVC products, medical devices, automotive components, cable insulation, and consumer goods.

The most widely used plasticizers belong to the phthalate family, though alternatives like adipates, citrates, and bio-based options have gained prominence due to environmental and health concerns. Regardless of type, all plasticizers face the same fundamental challenge: they’re not chemically bonded to the polymer matrix, making them susceptible to migration and loss over time.

When plasticizers escape from materials, the consequences extend far beyond aesthetics. Products become rigid, crack under stress, lose their protective properties, and ultimately fail prematurely. This degradation process, known as embrittlement, represents a significant concern for manufacturers, quality control specialists, and end-users alike.

⚠️ The Science Behind Plasticizer Migration

Plasticizer loss occurs through several distinct mechanisms, each influenced by environmental conditions and material composition. Understanding these pathways enables better prediction and prevention strategies.

Volatilization: The Primary Loss Mechanism

Volatilization represents the most common route for plasticizer depletion. Higher temperatures accelerate molecular movement, allowing plasticizers to evaporate from the material surface. This explains why products exposed to heat—such as automotive dashboards, outdoor cables, or equipment near machinery—experience faster degradation.

The rate of volatilization depends on the plasticizer’s molecular weight, vapor pressure, and the polymer’s structure. Low molecular weight plasticizers offer excellent initial flexibility but evaporate quickly, while high molecular weight alternatives provide better permanence at the cost of reduced processing efficiency.

Extraction and Leaching

Contact with liquids, oils, or other materials can extract plasticizers through diffusion. Medical tubing, food packaging, and industrial hoses face particular risks when exposed to solvents, cleaning agents, or biological fluids. The compatibility between the plasticizer and contacting substance determines extraction severity.

Water exposure poses challenges too, especially for hydrophilic plasticizers. Repeated wetting and drying cycles create pathways for plasticizer migration, gradually depleting the material’s flexibility reserves.

Migration to Adjacent Materials

Plasticizers naturally migrate toward materials with higher affinity, following concentration gradients. This phenomenon causes problems in multi-material assemblies where flexible components contact rigid plastics, paints, adhesives, or other polymers. The plasticizer transfers to the neighboring material, leaving the original product brittle while potentially damaging the recipient material.

🎯 Early Warning Signs of Plasticizer Loss

Detecting plasticizer depletion before catastrophic failure occurs provides opportunities for intervention, replacement scheduling, and quality improvements. Several observable indicators signal developing problems.

Visual and Tactile Changes

Early-stage plasticizer loss manifests through subtle appearance changes. Materials may develop a chalky or dusty surface as the exposed polymer layer loses flexibility and begins microcracking. Colors often fade or shift as the refractive properties change with plasticizer concentration.

Touch reveals important information too. Products feeling harder, less pliable, or sticky indicate progressing degradation. The “hand feel” test, while subjective, provides quick screening for experienced quality personnel.

Surface Cracking and Crazing

As embrittlement advances, stress concentrations create visible cracks. These typically appear first in high-stress areas—corners, bends, or attachment points. Crazing, characterized by networks of fine surface cracks, indicates advanced plasticizer depletion requiring immediate attention.

Dimensional Changes

Plasticizer loss causes materials to shrink slightly as polymer chains pack more tightly. Precision components may fail tolerance requirements, seals might leak, and assembled products could experience fit problems. Regular dimensional monitoring catches these changes before functional failures occur.

🔍 Professional Detection and Testing Methods

Beyond visual inspection, sophisticated testing methods quantify plasticizer content and predict remaining service life. Implementing appropriate testing protocols depends on application criticality, production volume, and available resources.

Differential Scanning Calorimetry (DSC)

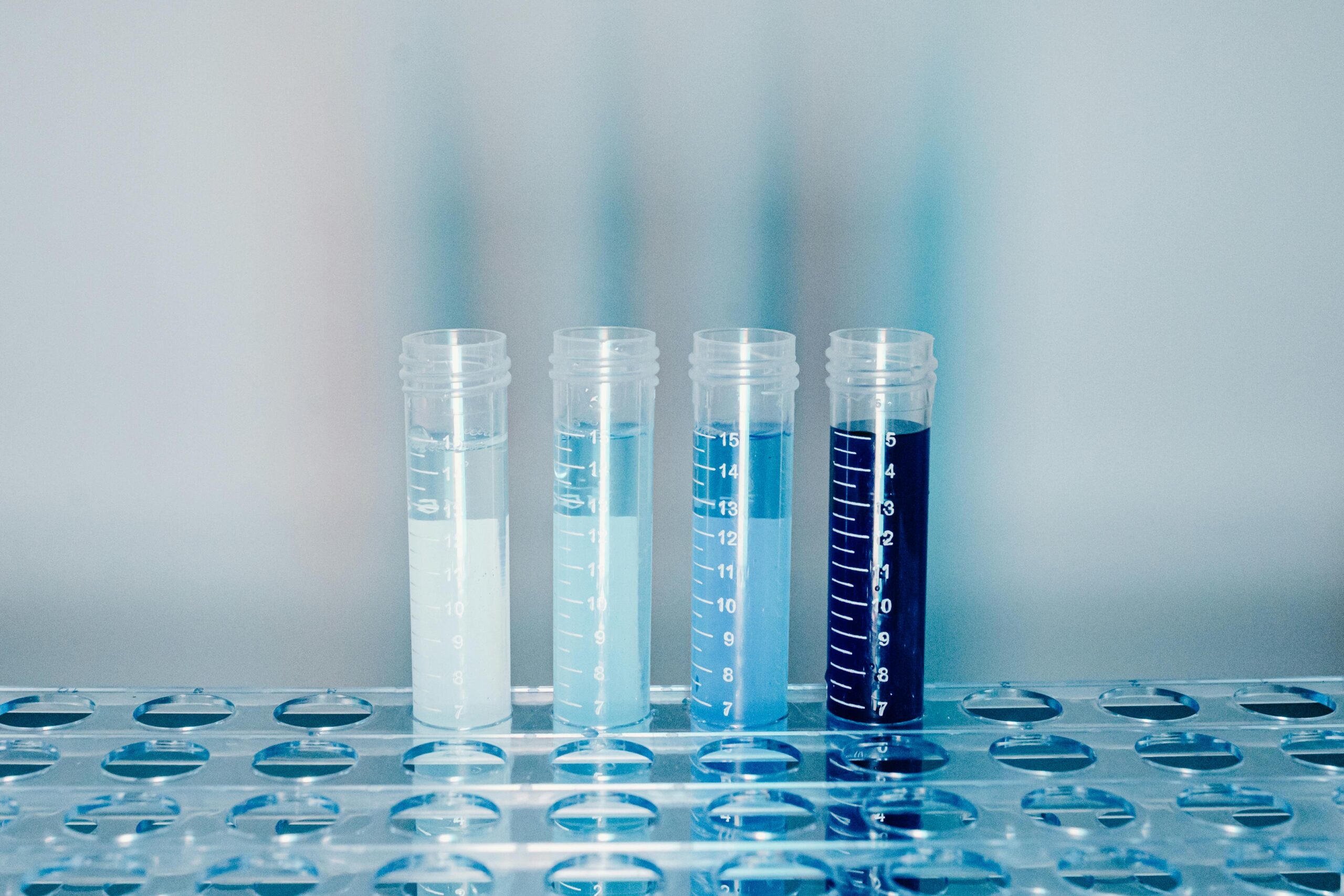

DSC measures thermal transitions within materials, revealing glass transition temperature shifts that correlate directly with plasticizer content. As plasticizer depletes, the glass transition temperature increases, indicating reduced flexibility. This non-destructive technique requires minimal sample preparation and provides quantitative results within hours.

Laboratories use DSC for quality control, failure analysis, and formulation development. Comparing fresh samples against aged materials establishes degradation rates and predicts field performance.

Thermogravimetric Analysis (TGA)

TGA precisely measures weight loss as samples heat under controlled conditions. The temperature and magnitude of weight loss events identify plasticizer types and quantify their concentration. This method excels at detecting volatile components and comparing formulations.

Combined TGA-DSC instruments provide complementary information, correlating thermal events with compositional changes for comprehensive material characterization.

Extraction and Chromatography

Solvent extraction followed by gas or liquid chromatography represents the gold standard for plasticizer quantification. Samples dissolve in appropriate solvents, separating plasticizers from the polymer matrix. Chromatographic analysis then identifies and quantifies specific plasticizer compounds with exceptional accuracy.

This approach enables formulation verification, contamination detection, and regulatory compliance testing. The method’s precision makes it ideal for critical applications in medical, food-contact, and aerospace industries.

Fourier Transform Infrared Spectroscopy (FTIR)

FTIR identifies chemical functional groups through their characteristic infrared absorption patterns. While not as quantitative as chromatography for plasticizer content, FTIR rapidly screens materials, detects surface degradation, and identifies unexpected additives or contaminants.

Portable FTIR instruments enable field testing, bringing laboratory capabilities to manufacturing floors or service locations. This accessibility makes FTIR valuable for routine quality checks and incoming material verification.

Mechanical Property Testing

Direct measurement of flexibility, tensile strength, elongation at break, and hardness provides functional assessment of plasticizer effectiveness. Shore hardness testing, particularly accessible and quick, tracks embrittlement progression through simple surface measurements.

Establishing baseline mechanical properties for new materials enables percentage-based acceptance criteria. When measured properties deviate beyond specified tolerances, investigation and action protocols activate.

🛡️ Implementing Effective Monitoring Programs

Systematic monitoring transforms sporadic testing into actionable intelligence, catching problems early while building knowledge about material behavior under real-world conditions.

Risk-Based Testing Schedules

Not all products require identical monitoring intensity. Critical safety components, items in harsh environments, and products with limited replacement opportunities warrant frequent testing. Lower-risk applications may need only periodic spot checks or end-of-life verification.

Develop testing matrices considering exposure conditions, material composition, historical performance, and failure consequences. Allocate resources where early detection provides greatest value.

Environmental Data Integration

Temperature, humidity, chemical exposure, and UV radiation all influence plasticizer loss rates. Correlating environmental monitoring with material testing reveals relationships between conditions and degradation, enabling predictive maintenance scheduling.

Modern IoT sensors provide continuous environmental data at minimal cost. Combining this information with periodic material testing builds sophisticated models predicting when products will require replacement.

Sample Retention and Aging Studies

Maintaining reference samples under controlled conditions establishes performance baselines and validates testing methods. Accelerated aging studies, exposing materials to elevated temperatures or aggressive environments, predict long-term field behavior in compressed timeframes.

Compare naturally aged field samples against laboratory predictions to refine models and improve accuracy. This iterative approach continuously enhances understanding of material longevity.

💡 Prevention Strategies for Extended Product Life

While detection enables responsive action, prevention strategies address plasticizer loss at its source, maximizing product durability from the start.

Formulation Optimization

Selecting plasticizers with appropriate molecular weights, vapor pressures, and compatibility profiles significantly impacts permanence. High molecular weight plasticizers sacrifice some processing ease but deliver superior retention, especially in elevated temperature applications.

Blending multiple plasticizer types can balance initial flexibility with long-term retention. Primary plasticizers provide immediate workability while secondary plasticizers with lower volatility maintain flexibility over time.

Protective Barriers and Coatings

Physical barriers slow plasticizer migration and volatilization. UV-resistant coatings protect against photodegradation while reducing evaporative losses. Multilayer constructions place barrier films between plasticized layers and aggressive environments.

For cables and tubes, outer sheaths using more stable polymers shield inner plasticized layers from direct environmental exposure. This approach extends service life without compromising internal flexibility requirements.

Environmental Control

When possible, controlling service conditions dramatically improves longevity. Temperature reduction, UV shielding, chemical isolation, and moisture management all slow degradation processes. Design considerations incorporating these protections early prove more cost-effective than dealing with premature failures.

Material Selection and Alternatives

For applications with extreme longevity requirements or harsh conditions, alternatives to traditional plasticized polymers deserve consideration. Thermoplastic elastomers, inherently flexible without plasticizers, eliminate migration concerns entirely. While potentially more expensive initially, life-cycle costs may favor these materials when replacement expenses and downtime factor into calculations.

📊 Building Business Cases for Proactive Monitoring

Implementing comprehensive detection programs requires investment in equipment, training, and processes. Justifying these expenditures demands clear demonstration of value and return.

Failure Cost Analysis

Document complete failure costs including material replacement, labor, downtime, warranty claims, liability exposure, and reputation damage. Early detection programs preventing even occasional catastrophic failures often pay for themselves many times over.

Quality Assurance Enhancement

Material testing data strengthens quality control, catches supplier variations, verifies incoming materials, and supports corrective action decisions. These benefits extend beyond plasticizer monitoring, improving overall manufacturing quality.

Competitive Advantages

Products demonstrating superior longevity command premium pricing, reduce customer total cost of ownership, and differentiate brands in competitive markets. Marketing materials supported by rigorous testing data build customer confidence and justify quality claims.

🌍 Regulatory and Sustainability Considerations

Plasticizer selection and monitoring intersect with evolving regulations and sustainability initiatives worldwide. Proactive programs address these concerns while avoiding compliance surprises.

Phthalate restrictions in consumer products, medical devices, and toys drive formulation changes toward alternative plasticizers. Monitoring programs must adapt to new chemistries with potentially different aging behaviors. Testing protocols developed for traditional phthalates may require modification for alternative plasticizers.

Sustainability pressures favor longer product lifespans over frequent replacements. Demonstrating extended durability through monitoring data supports environmental claims and appeals to eco-conscious customers. Proper plasticizer management directly contributes to circular economy objectives by maximizing material utility before end-of-life.

🚀 Future Technologies and Emerging Solutions

Advances in materials science, sensor technology, and data analytics promise enhanced capabilities for plasticizer monitoring and product longevity.

Embedded Sensors and Smart Materials

Research into materials containing embedded sensors enables real-time flexibility monitoring without destructive testing. Color-changing indicators triggered by specific flexibility thresholds provide visual warnings when replacement becomes necessary. While still emerging, these technologies will revolutionize maintenance scheduling and quality assurance.

Artificial Intelligence and Predictive Modeling

Machine learning algorithms processing environmental data, testing results, and failure records identify patterns invisible to traditional analysis. These models predict individual product lifespans with increasing accuracy, optimizing maintenance schedules and inventory management.

Bio-Based and Reactive Plasticizers

New plasticizer generations derived from renewable resources or designed to chemically bond with polymer matrices address permanence concerns while meeting sustainability goals. As these materials mature commercially, monitoring protocols will evolve to address their unique characteristics.

🎓 Training and Organizational Implementation

Technology and procedures alone cannot ensure successful monitoring programs. Organizational commitment, trained personnel, and established workflows transform testing data into actionable improvements.

Develop clear testing protocols specifying sample collection, handling, analysis methods, and acceptance criteria. Document procedures enable consistent execution regardless of personnel changes and provide audit trails for quality systems.

Train operators, quality technicians, and engineers on plasticizer fundamentals, degradation mechanisms, testing interpretation, and response procedures. Understanding the “why” behind testing improves engagement and problem-solving when unexpected results appear.

Establish communication channels ensuring testing results reach decision-makers promptly. Rapid response to concerning trends prevents isolated measurements from escalating into widespread failures.

🔧 Practical Implementation Roadmap

Organizations beginning plasticizer monitoring programs benefit from structured implementation approaches balancing thoroughness with practical constraints.

Phase One: Assessment and Planning – Inventory products containing plasticizers, assess failure risks and consequences, prioritize monitoring needs, and establish baseline testing requirements. This foundation ensures resources focus where they provide maximum value.

Phase Two: Capability Development – Acquire necessary testing equipment or establish laboratory partnerships, develop testing procedures, train personnel, and validate methods against known standards. Build confidence in measurement accuracy before making critical decisions based on results.

Phase Three: Initial Testing and Baseline Establishment – Test representative samples across product lines and exposure conditions, document baseline properties, and begin accumulating aging data. Early results may reveal unexpected variations requiring formulation or process adjustments.

Phase Four: Routine Monitoring and Refinement – Implement scheduled testing programs, correlate results with environmental conditions and service history, refine testing frequencies based on observed degradation rates, and continuously improve prediction accuracy.

Phase Five: Integration and Optimization – Incorporate monitoring data into quality systems, maintenance scheduling, design improvements, and supplier management. Mature programs influence decisions throughout product lifecycles, from formulation selection through end-of-life planning.

💪 Securing Long-Term Material Performance

Plasticizer loss and resulting embrittlement represent manageable challenges when addressed systematically through early detection and preventive strategies. Materials science provides robust tools for monitoring degradation while formulation advances and protective measures extend product lifespans dramatically.

Organizations implementing comprehensive monitoring programs gain competitive advantages through improved reliability, reduced warranty costs, and enhanced customer satisfaction. The investment in testing capabilities and prevention strategies pays dividends across multiple dimensions—quality improvement, risk reduction, regulatory compliance, and sustainability advancement.

Success requires balancing technical rigor with practical implementation, allocating resources based on risk assessment, and maintaining organizational commitment through leadership support and trained personnel. As technologies advance and regulations evolve, monitoring programs must adapt while maintaining focus on the fundamental goal: keeping products flexible, functional, and reliable throughout their intended service lives.

The path forward combines proven testing methodologies with emerging technologies, traditional materials knowledge with sustainable alternatives, and reactive problem-solving with proactive prevention. Organizations embracing this comprehensive approach protect their investments, satisfy their customers, and position themselves for success in markets increasingly valuing durability and longevity.

Toni Santos is a preservation specialist and material conservator specializing in the restoration of botanical specimens, the stabilization of chemical fibers, and the structural analysis of degraded organic materials. Through an interdisciplinary and technically-focused approach, Toni investigates how natural and synthetic materials decay over time — and how to reverse, slow, and map these processes for cultural and scientific preservation. His work is grounded in a fascination with materials not only as physical substrates, but as carriers of environmental history. From botanical tissue restoration to fiber stabilization and decay structure mapping, Toni uncovers the chemical and biological pathways through which organic matter degrades and how intervention can preserve material integrity. With a background in conservation science and environmental material studies, Toni blends laboratory analysis with fieldwork to reveal how plants and fibers respond to environmental stressors, aging, and preservation strategies. As the creative mind behind qorvalyn, Toni curates preservation case studies, structural decay analyses, and conservation protocols that advance the technical understanding of material longevity, botanical integrity, and fiber resilience. His work is a tribute to: The recovery and stabilization of Botanical Material Restoration The chemical treatment of Chemical Fiber Preservation The mitigation strategies of Environmental Decay Reduction The diagnostic visualization of Preservation Structure Mapping Whether you're a conservation professional, material researcher, or steward of fragile collections, Toni invites you to explore the science of preservation — one fiber, one specimen, one intervention at a time.