Understanding textile fiber composition is essential for achieving optimal fabric care and treatment outcomes. Whether you’re a professional cleaner, fashion designer, or simply someone who wants to preserve their favorite garments, knowing what your fabrics are made of makes all the difference.

🧵 Why Fiber Identification Matters More Than You Think

Every day, millions of garments are damaged because people don’t understand their textile composition. A wool sweater shrinks in hot water, a silk blouse loses its luster from harsh detergents, or a polyester shirt melts under a too-hot iron. These common disasters are entirely preventable with proper fiber knowledge.

The fiber file concept represents a systematic approach to cataloging and understanding textile materials. By creating a comprehensive reference system for different fiber types, their characteristics, and appropriate treatment methods, we can dramatically improve fabric care outcomes across all settings—from home laundry rooms to professional textile restoration facilities.

Modern textiles are increasingly complex, with many garments containing blends of natural and synthetic fibers. This complexity makes fiber identification even more critical. A shirt labeled as “cotton blend” might contain anywhere from 5% to 95% cotton, with the remainder being polyester, rayon, spandex, or other materials. Each component requires specific consideration.

📋 The Major Fiber Categories You Need to Know

Textile fibers fall into several main categories, each with distinct properties and care requirements. Understanding these categories forms the foundation of any comprehensive fiber file system.

Natural Cellulosic Fibers: Plant-Based Materials

Cotton, linen, hemp, and ramie belong to this category. These fibers are breathable, absorbent, and generally durable. Cotton is the most widely used natural fiber globally, prized for its comfort and versatility. Linen, derived from flax plants, offers excellent heat conductivity, making it ideal for warm weather clothing.

These fibers can typically withstand higher washing temperatures than protein-based or synthetic materials. However, they’re prone to shrinkage if exposed to excessive heat during washing or drying. They also tend to wrinkle easily, though linen’s natural creases are often considered part of its charm.

Treatment considerations for cellulosic fibers include using appropriate water temperatures (usually warm to hot for whites, cool for colors), avoiding chlorine bleach on colored items, and using moderate iron temperatures. These fibers can tolerate most commercial detergents well.

Protein-Based Natural Fibers: Animal Origins

Wool, silk, cashmere, mohair, and alpaca represent the protein fiber category. These luxurious materials require gentler treatment than their plant-based counterparts. Protein fibers are particularly sensitive to pH extremes, high temperatures, and agitation.

Wool is remarkably resilient and naturally stain-resistant due to its scaled structure and lanolin content. However, this same structure makes it vulnerable to felting when exposed to heat and friction. Silk, while incredibly strong for its weight, degrades when exposed to sunlight and perspiration.

These fibers demand cool water washing, minimal agitation, and specialized detergents formulated for protein-based materials. Professional dry cleaning is often recommended for valuable items. Air drying flat is preferable to prevent stretching or distortion.

Synthetic Fibers: Laboratory-Created Performance

Polyester, nylon, acrylic, spandex, and polypropylene are engineered fibers designed to offer specific performance characteristics. Polyester resists wrinkles and shrinking, nylon provides exceptional strength and elasticity, and spandex delivers unmatched stretch.

Synthetic fibers are generally easy to care for, tolerating repeated washing without significant degradation. However, they’re thermoplastic, meaning they can melt or deform under high heat. This makes temperature control crucial during ironing and drying.

Many synthetic fibers are oleophilic, attracting and holding oil-based stains more readily than natural fibers. This characteristic requires pre-treatment of greasy stains and sometimes specialized stain removal techniques. Synthetic fibers also tend to develop static electricity and may pill with wear.

🔍 Practical Methods for Identifying Textile Fibers

Building an effective fiber file requires accurate identification methods. Several techniques exist, ranging from simple visual examination to laboratory testing.

The Burn Test: A Classic Identification Method

The burn test involves carefully burning a small fiber sample and observing how it burns, the smell produced, and the residue left behind. Cotton and linen burn quickly with a paper-like smell and leave soft, gray ash. Wool and silk burn slowly, smell like burning hair, and leave crushable black beads. Synthetics often melt rather than burn, producing plastic-like odors and hard beads.

While informative, the burn test has limitations. It requires damaging the fabric, can be dangerous if not performed carefully, and provides limited information about fiber blends. Modern identification methods offer safer alternatives.

Microscopic Examination Techniques

Under magnification, different fibers display distinctive structural characteristics. Cotton appears as a twisted ribbon with a central canal, wool shows overlapping scales, silk appears as a smooth rod, and synthetics typically have uniform, manufactured appearances.

Digital microscopy has made this technique more accessible, with smartphone attachments and USB microscopes bringing professional-grade magnification to non-laboratory settings. Building a visual fiber file with microscopic images creates an invaluable reference tool.

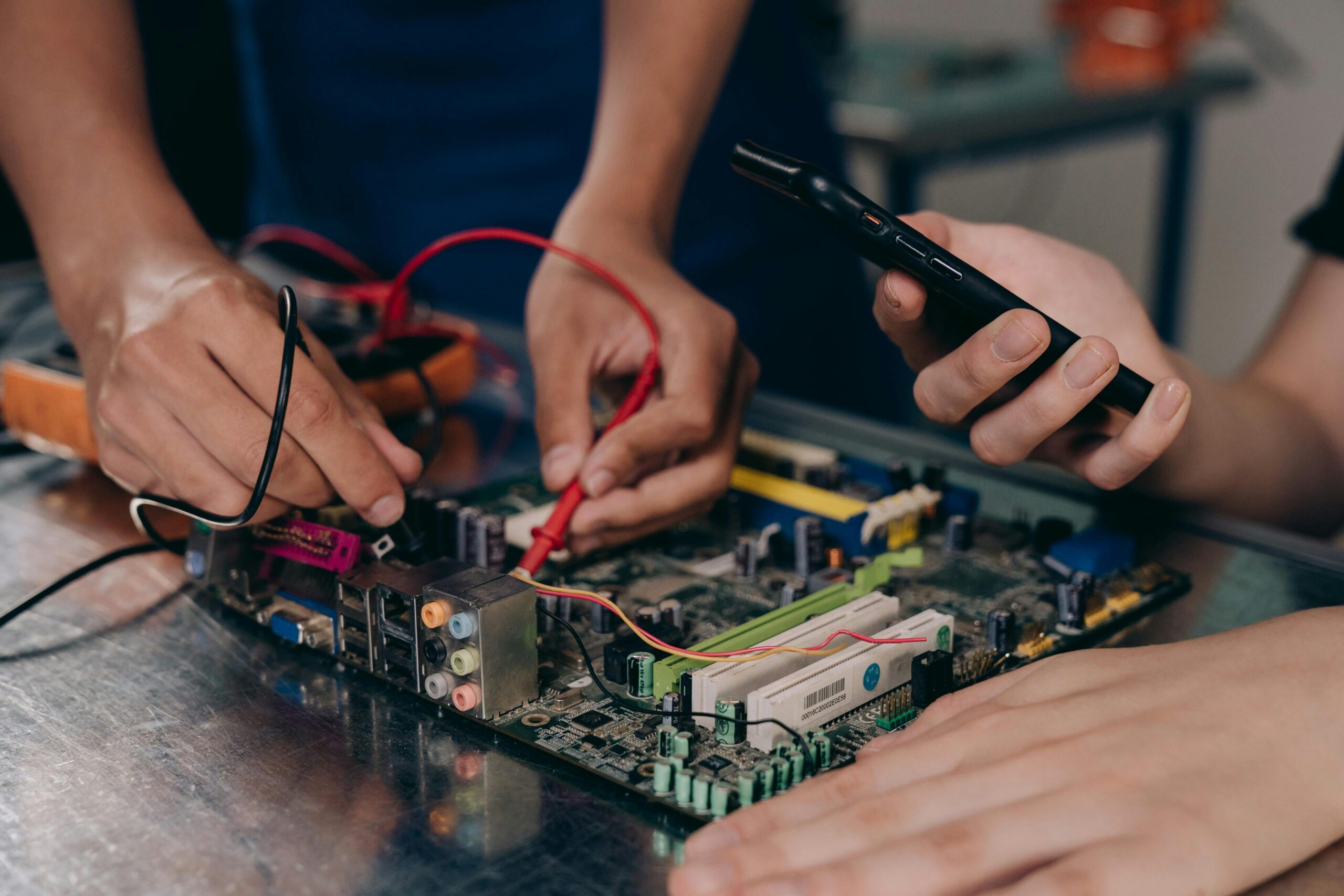

Chemical Testing Procedures

Various chemical reagents react differently with specific fiber types. Acetone dissolves acetate but not other fibers. Concentrated sulfuric acid dissolves cellulosic fibers while leaving protein and synthetic fibers intact. These tests require careful handling and proper safety equipment.

Solubility testing offers high accuracy but demands technical knowledge and controlled conditions. Professional textile laboratories use sophisticated instruments including infrared spectroscopy and scanning electron microscopy for definitive identification.

💡 Creating Your Personal Fiber File System

An organized fiber file serves as an invaluable reference for optimal treatment decisions. Whether you’re managing a professional cleaning business or simply want to better care for your wardrobe, a systematic approach pays dividends.

Start by collecting fiber samples from common textiles you encounter. Store these in a labeled binder with clear sleeves or small envelopes. Include information about fiber type, common trade names, visual characteristics, tactile properties, and recommended care procedures.

Document your findings photographically. Close-up images of fabric surfaces, microscopic views, and burn test results create visual references that accelerate future identification. Digital organization through smartphone apps or computer databases makes this information instantly accessible.

Include actual care label information from successfully treated garments. Over time, you’ll develop a personalized knowledge base reflecting your specific experiences and the textile types you most commonly encounter.

🧪 Advanced Treatment Considerations for Complex Blends

Modern textiles frequently combine multiple fiber types to achieve desired performance characteristics. A typical athletic shirt might contain polyester for moisture wicking, cotton for comfort, and spandex for stretch. Each component influences how the fabric should be treated.

The general rule for blends is to follow care requirements for the most delicate fiber present. A garment that’s 95% cotton and 5% spandex should be treated according to spandex guidelines, avoiding high heat that could damage the elastic component.

However, this conservative approach isn’t always optimal. Understanding the specific properties and percentages of blend components allows for more nuanced treatment decisions. A fabric with minimal synthetic content might tolerate treatments typically reserved for natural fibers.

Stain Removal Strategies Based on Fiber Composition

Fiber type dramatically affects stain removal success. Protein-based stains like blood respond better to enzyme treatments on cellulosic and synthetic fibers than on protein-based textiles, where enzymes might damage the fabric itself.

Oil-based stains penetrate synthetic fibers more deeply due to their chemical affinity, requiring pre-treatment with solvents or surfactants before washing. Natural fibers generally release oil-based stains more readily with appropriate detergent action.

Tannin stains from coffee, tea, and wine need acidic treatment on cellulosic fibers but may set permanently if heat is applied before removal. Understanding these interactions prevents common stain-setting mistakes that render garments permanently damaged.

🌟 Professional Applications of Fiber File Knowledge

For textile professionals, comprehensive fiber knowledge represents a competitive advantage. Dry cleaners who accurately identify fiber content reduce damage claims and improve customer satisfaction. Costume designers select appropriate materials for specific performance requirements. Textile conservators preserve historical garments through informed treatment decisions.

Quality control in manufacturing relies on fiber verification to ensure products meet specifications. Counterfeit detection often begins with fiber analysis, revealing synthetic substitutes masquerading as natural luxury fibers. Insurance adjusters assess damage claims more accurately with proper fiber identification.

The textile recycling industry depends on fiber sorting to create value from used garments. Different fiber types have different recycling pathways, and contamination with incompatible materials reduces recycled material quality. Accurate identification enables efficient sorting processes.

🛡️ Protecting Investment Pieces Through Proper Fiber Care

Luxury garments represent significant financial investments that deserve optimal care. A cashmere sweater, silk designer dress, or fine wool suit can last decades with proper treatment but deteriorate rapidly under incorrect care.

Understanding fiber composition helps you evaluate care service providers. When a dry cleaner claims they can safely clean any garment, fiber knowledge helps you assess whether their methods align with best practices for specific materials.

Home care of investment pieces becomes less intimidating with solid fiber knowledge. Hand washing cashmere in cool water with specialized wool detergent saves professional cleaning costs while maintaining garment quality. Knowing that silk can be gently hand washed in many cases expands your care options.

🌍 Environmental Considerations in Fiber Treatment

Different fibers have varying environmental impacts during both production and care. Natural fibers are generally biodegradable but may require significant water, pesticides, and land for cultivation. Synthetic fibers derive from petroleum but often require less water and energy during use and care.

Treatment decisions affect environmental footprint. Washing in cold water significantly reduces energy consumption for all fiber types. Air drying eliminates dryer energy use. Understanding which fibers truly need professional dry cleaning versus those that can be safely laundered at home reduces chemical solvent usage.

Extending garment lifespan through proper fiber-specific care represents the most sustainable approach. A well-maintained garment that lasts twice as long effectively halves its environmental impact per wear.

📱 Technology Tools for Modern Fiber Identification

Smartphone applications now assist with fiber identification and care recommendations. Some apps use image recognition to identify fabric types from photographs, while others provide searchable databases of care symbols and fiber characteristics.

Digital microscope attachments transform smartphones into powerful identification tools, revealing fiber structures at useful magnifications. These accessories cost a fraction of traditional microscopes while providing adequate resolution for most identification needs.

Online databases and forums connect textile enthusiasts and professionals, sharing identification tips and treatment experiences. Building a digital fiber file using cloud storage ensures your reference information remains accessible across devices and locations.

🎯 Putting Fiber Knowledge Into Daily Practice

Translating fiber file knowledge into practical action requires developing systematic habits. Before purchasing any garment, examine the fiber content label and consider care requirements. A beautiful item that requires expensive professional care might not suit your lifestyle or budget.

When preparing to wash clothing, sort not just by color but by fiber type and care requirements. Washing cotton towels separately from synthetic activewear optimizes results for both categories. This extra step prevents compromises that leave some items less clean or others potentially damaged.

Keep a quick reference guide near your laundry area listing appropriate water temperatures, detergent types, and drying methods for common fiber categories. This simple tool prevents costly mistakes during busy moments when you might otherwise guess at appropriate settings.

✨ Mastering Textile Composition for Lasting Results

Building and utilizing a comprehensive fiber file transforms your relationship with textiles. What once seemed mysterious becomes understandable and manageable. Garments last longer, look better, and perform as intended when treated according to their specific fiber composition.

The investment in fiber knowledge pays continuous dividends. Reduced garment replacement costs, fewer professional cleaning expenses, and the satisfaction of properly maintaining your possessions all stem from understanding textile composition fundamentals.

Start building your fiber file today. Collect samples, document characteristics, experiment with identification methods, and record successful treatment outcomes. Over time, you’ll develop an intuitive understanding that makes optimal fiber treatment second nature, unlocking the full potential of every textile you encounter.

Toni Santos is a preservation specialist and material conservator specializing in the restoration of botanical specimens, the stabilization of chemical fibers, and the structural analysis of degraded organic materials. Through an interdisciplinary and technically-focused approach, Toni investigates how natural and synthetic materials decay over time — and how to reverse, slow, and map these processes for cultural and scientific preservation. His work is grounded in a fascination with materials not only as physical substrates, but as carriers of environmental history. From botanical tissue restoration to fiber stabilization and decay structure mapping, Toni uncovers the chemical and biological pathways through which organic matter degrades and how intervention can preserve material integrity. With a background in conservation science and environmental material studies, Toni blends laboratory analysis with fieldwork to reveal how plants and fibers respond to environmental stressors, aging, and preservation strategies. As the creative mind behind qorvalyn, Toni curates preservation case studies, structural decay analyses, and conservation protocols that advance the technical understanding of material longevity, botanical integrity, and fiber resilience. His work is a tribute to: The recovery and stabilization of Botanical Material Restoration The chemical treatment of Chemical Fiber Preservation The mitigation strategies of Environmental Decay Reduction The diagnostic visualization of Preservation Structure Mapping Whether you're a conservation professional, material researcher, or steward of fragile collections, Toni invites you to explore the science of preservation — one fiber, one specimen, one intervention at a time.