Understanding and mitigating hidden threats in our environments requires sophisticated tools and methodologies. Risk-layer mapping emerges as a critical framework for identifying, analyzing, and managing mechanical, chemical, and biological hazards that often remain invisible until disaster strikes.

🔍 The Foundation of Risk-Layer Mapping in Modern Safety Management

Risk-layer mapping represents a comprehensive approach to threat assessment that goes beyond traditional safety protocols. This methodology involves creating detailed visual and analytical representations of various hazard types across multiple operational layers, allowing organizations to identify vulnerabilities before they manifest into actual incidents. The process combines spatial analysis, temporal data, and probabilistic modeling to create actionable intelligence for decision-makers.

The fundamental principle behind risk-layer mapping is that threats rarely exist in isolation. Instead, they interact with environmental factors, operational processes, and human activities to create complex risk scenarios. By mapping these interactions across different layers, safety professionals can develop more effective mitigation strategies and allocate resources where they’re needed most.

⚙️ Mechanical Threats: The Physical Dangers Lurking in Plain Sight

Mechanical hazards represent some of the most immediate and visible threats in industrial and operational environments. These dangers include moving machinery parts, falling objects, pressurized systems, and structural failures that can cause severe injuries or fatalities. Despite their apparent visibility, mechanical threats often hide behind routine operations and familiar processes.

Identifying High-Risk Mechanical Zones Through Layered Analysis

Risk-layer mapping for mechanical threats begins with comprehensive facility assessments that identify all potential sources of mechanical energy and movement. This includes conveyor systems, rotating equipment, hydraulic presses, and automated machinery. Each identified hazard is then categorized based on its severity potential, frequency of exposure, and existing control measures.

The mapping process creates distinct layers for different mechanical threat categories:

- Crushing and pinch point zones where body parts could become trapped

- Impact areas where falling or ejected objects pose risks

- High-pressure system locations with potential for explosive decompression

- Moving vehicle pathways and intersection points

- Structural integrity concerns including load-bearing elements

Dynamic Risk Assessment in Mechanical Environments

Unlike static safety audits, risk-layer mapping incorporates temporal elements that account for changing operational conditions. Manufacturing facilities operate differently during shift changes, maintenance windows, and peak production periods. Each operational state presents unique mechanical risk profiles that must be mapped and understood.

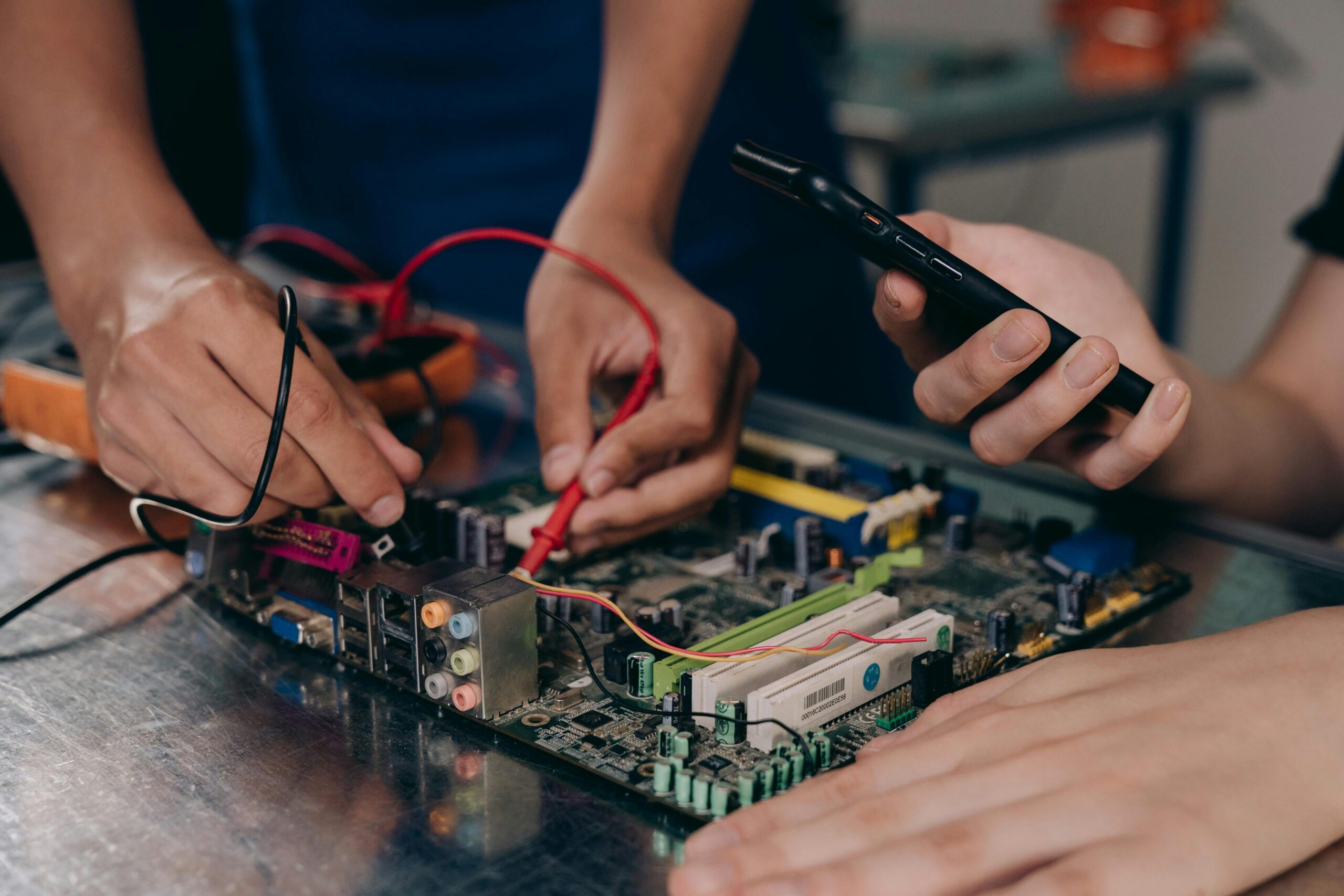

Advanced organizations now employ sensor networks and IoT devices to create real-time mechanical risk maps that update automatically as conditions change. These systems can detect vibration anomalies, pressure fluctuations, and movement patterns that signal developing mechanical failures before catastrophic events occur.

🧪 Chemical Hazards: The Invisible Threat Matrix

Chemical threats present unique challenges because many are imperceptible to human senses until exposure has already occurred. Toxic gases, corrosive liquids, reactive substances, and carcinogenic compounds permeate countless industrial, healthcare, and research environments. Risk-layer mapping for chemical hazards requires sophisticated understanding of chemical properties, interaction potentials, and dispersion patterns.

Building Comprehensive Chemical Risk Layers

Effective chemical risk mapping begins with complete inventory management that tracks every hazardous substance within a facility. This inventory forms the foundation for understanding potential exposure scenarios. Each chemical is evaluated not just for its inherent properties, but for its location, quantity, containment systems, and proximity to other substances or ignition sources.

The layered approach to chemical risk mapping considers multiple dimensions simultaneously. Geographic layers show where chemicals are stored, used, and transported. Temporal layers indicate when specific chemicals are present or being actively handled. Interaction layers model what happens if containment fails or incompatible substances mix.

Vapor Clouds, Spill Zones, and Dispersion Modeling

One of the most valuable applications of risk-layer mapping for chemical threats involves atmospheric dispersion modeling. When volatile chemicals escape containment, their movement through an environment depends on ventilation patterns, temperature gradients, and molecular weight. Advanced mapping systems incorporate computational fluid dynamics to predict how chemical clouds would spread under various conditions.

These predictive models create risk zones that extend far beyond the immediate release point. Emergency responders can use these maps to establish appropriate evacuation perimeters, position decontamination resources, and plan ingress routes that minimize exposure. The same models help facility designers optimize ventilation systems and locate chemical storage areas to minimize worst-case scenario impacts.

🦠 Biological Threats: Mapping the Microbial Landscape

Biological hazards encompass infectious agents, allergens, toxins produced by living organisms, and biological vectors that transmit disease. The COVID-19 pandemic dramatically illustrated how biological threats can disrupt entire societies, but these risks exist continuously in healthcare facilities, research laboratories, food processing plants, and agricultural operations.

Contamination Pathways and Transmission Vectors

Risk-layer mapping for biological threats requires understanding how pathogens move through environments and populations. Unlike mechanical or chemical hazards that follow physical laws predictably, biological agents can reproduce, mutate, and spread through complex transmission chains. Mapping these risks involves epidemiological modeling combined with environmental sampling data.

Critical biological risk layers include high-touch surfaces where pathogens accumulate, ventilation systems that can distribute airborne agents, water systems susceptible to contamination, and areas where immunocompromised individuals concentrate. Each layer represents a potential amplification point where biological threats can intensify before spreading further.

Biocontainment Zones and Barrier Integrity

Facilities that work with dangerous biological materials establish biocontainment through multiple physical and procedural barriers. Risk-layer mapping visualizes these containment systems as concentric protection zones, with the most hazardous materials at the center surrounded by progressively less restrictive areas. This approach helps identify single points of failure where barrier breaches could cascade across containment levels.

Regular integrity testing of biosafety cabinets, air handling systems, and personal protective equipment generates data that feeds into risk maps. When equipment performance degrades or procedural compliance lapses, the corresponding risk layers can be updated to reflect increased threat levels and trigger corrective actions.

🗺️ Integrating Multiple Threat Categories into Unified Risk Maps

The true power of risk-layer mapping emerges when mechanical, chemical, and biological threats are visualized together. Many actual incidents involve cascading failures across multiple threat categories. A mechanical failure might rupture a chemical storage tank, while a chemical spill might contaminate biological research materials.

Identifying Dangerous Synergies and Cascade Scenarios

Integrated risk mapping reveals scenarios that single-threat assessments would miss entirely. An earthquake represents a mechanical threat to structural integrity, but its risk mapping must account for how structural failures could breach chemical containment or compromise biological safety systems. Similarly, a chemical fire generates toxic combustion products while potentially overwhelming mechanical firefighting systems.

Sophisticated mapping platforms use scenario modeling to explore these interactions systematically. By running thousands of simulations with varying initial conditions, these systems identify the most dangerous threat combinations and the most effective intervention points. This intelligence guides investment in redundant systems, emergency response planning, and facility design modifications.

📊 Technology Enablers for Advanced Risk-Layer Mapping

Modern risk-layer mapping leverages multiple technological platforms to collect, analyze, and visualize threat data. Geographic Information Systems (GIS) provide the spatial framework for organizing risk information. Building Information Modeling (BIM) adds three-dimensional architectural context. Sensor networks supply real-time environmental data that keeps maps current.

Data Sources That Power Comprehensive Threat Analysis

Effective risk mapping requires data integration from diverse sources. Maintenance records reveal mechanical system degradation patterns. Chemical inventory databases track hazardous substance movements. Environmental monitoring systems detect airborne contaminants and biological agents. Incident reports provide historical patterns that inform predictive models.

Machine learning algorithms increasingly process these data streams to identify patterns human analysts might miss. These systems can detect subtle correlations between seemingly unrelated variables, such as how specific weather conditions correlate with increased mechanical failures or how staffing levels influence chemical handling incident rates.

👥 Human Factors in Risk-Layer Mapping Implementation

Technology and methodology alone cannot ensure effective risk management. Human factors determine whether risk mapping translates into actual safety improvements. Workers must understand the maps, trust their accuracy, and have authority to act on the intelligence they provide. Safety cultures that punish error reporting will never obtain the data quality necessary for accurate risk mapping.

Training Workforce to Navigate Risk Intelligence

Risk maps only create value when people use them for decision-making. This requires training programs that teach workers at all levels how to interpret risk visualizations, understand probability concepts, and translate mapped threats into protective actions. The most effective training uses scenario-based exercises where teams navigate simulated emergencies using actual facility risk maps.

Frontline workers often possess invaluable local knowledge about hazards that formal assessments overlook. Creating feedback mechanisms where workers can contribute to risk maps improves accuracy while increasing buy-in for safety initiatives. Mobile applications that allow field personnel to report hazards directly into mapping systems have proven particularly effective.

🎯 Strategic Risk Mitigation Based on Layered Threat Intelligence

The ultimate purpose of risk-layer mapping is enabling more effective threat mitigation. By quantifying and visualizing risks across multiple dimensions, organizations can prioritize investments, design targeted interventions, and measure the effectiveness of control measures objectively.

Resource Allocation Guided by Risk Density Analysis

Risk-layer mapping reveals where threats concentrate most intensely. These high-risk zones warrant disproportionate resource allocation including enhanced monitoring, redundant safety systems, and more frequent inspections. Conversely, accurately mapped low-risk areas allow organizations to reduce unnecessary precautions and deploy those resources where they generate greater safety value.

Financial modeling combined with risk mapping enables cost-benefit analysis of competing safety investments. Organizations can quantify the risk reduction achieved per dollar spent, moving safety decisions from subjective judgments to data-driven optimization. This approach proves particularly valuable when defending safety budgets to financially-focused leadership.

🔄 Continuous Improvement Through Dynamic Risk Monitoring

Risk environments constantly evolve as processes change, equipment ages, and new threats emerge. Static risk assessments become obsolete quickly, creating false confidence that documented hazards remain accurate. Dynamic risk-layer mapping treats threat assessment as an ongoing process rather than a periodic activity.

Continuous monitoring systems automatically update risk maps as conditions change. When sensors detect equipment operating outside normal parameters, the associated mechanical risk layers adjust accordingly. When chemical inventory systems record new substance arrivals, chemical risk zones expand or contract. When biological monitoring identifies pathogen presence, contamination risk layers update in real-time.

Validation Through Incident Analysis and Near-Miss Data

Every incident and near-miss represents a validation opportunity for risk maps. When mapped high-risk zones generate actual incidents, this confirms the model’s predictive accuracy. When incidents occur in areas mapped as low-risk, this signals model deficiencies requiring correction. Systematic incident analysis feeds back into risk mapping algorithms, progressively improving their accuracy over time.

🌐 Regulatory Compliance and Risk-Layer Documentation

Many industries face regulatory requirements for documented risk assessments. Risk-layer mapping provides auditable evidence of systematic threat identification and analysis. The visual nature of risk maps communicates complex safety information to regulators more effectively than text-heavy compliance documents.

Regulatory inspectors increasingly expect to see dynamic risk management systems rather than static documentation. Organizations that can demonstrate real-time risk monitoring, automated anomaly detection, and data-driven mitigation prioritization establish credibility with oversight agencies. This proactive approach often results in greater regulatory flexibility and reduced inspection frequency.

🚀 The Future of Integrated Threat Intelligence

Risk-layer mapping continues evolving as new technologies and methodologies emerge. Artificial intelligence systems are beginning to predict threat evolution before traditional indicators become apparent. Augmented reality interfaces allow workers to visualize invisible chemical plumes and biological contamination zones overlaid on their actual environment.

The integration of risk mapping with digital twins creates unprecedented simulation capabilities. Organizations can test the safety implications of proposed process changes, equipment modifications, or facility expansions in virtual environments before implementing changes physically. This predictive capacity promises to prevent hazards from ever materializing rather than merely responding after exposure occurs.

The convergence of mechanical, chemical, and biological threat intelligence into unified risk frameworks represents a fundamental shift in safety management philosophy. Rather than treating different hazard categories as separate domains requiring distinct expertise, integrated risk-layer mapping recognizes that real-world threats interact across traditional boundaries. Organizations that embrace this comprehensive approach position themselves to identify hidden dangers before they manifest into tragedies, protecting both human lives and operational continuity in an increasingly complex threat environment.

Toni Santos is a preservation specialist and material conservator specializing in the restoration of botanical specimens, the stabilization of chemical fibers, and the structural analysis of degraded organic materials. Through an interdisciplinary and technically-focused approach, Toni investigates how natural and synthetic materials decay over time — and how to reverse, slow, and map these processes for cultural and scientific preservation. His work is grounded in a fascination with materials not only as physical substrates, but as carriers of environmental history. From botanical tissue restoration to fiber stabilization and decay structure mapping, Toni uncovers the chemical and biological pathways through which organic matter degrades and how intervention can preserve material integrity. With a background in conservation science and environmental material studies, Toni blends laboratory analysis with fieldwork to reveal how plants and fibers respond to environmental stressors, aging, and preservation strategies. As the creative mind behind qorvalyn, Toni curates preservation case studies, structural decay analyses, and conservation protocols that advance the technical understanding of material longevity, botanical integrity, and fiber resilience. His work is a tribute to: The recovery and stabilization of Botanical Material Restoration The chemical treatment of Chemical Fiber Preservation The mitigation strategies of Environmental Decay Reduction The diagnostic visualization of Preservation Structure Mapping Whether you're a conservation professional, material researcher, or steward of fragile collections, Toni invites you to explore the science of preservation — one fiber, one specimen, one intervention at a time.