Polymers are everywhere in modern industry, but their longevity depends on proper environmental control. Microclimate enclosures offer a sophisticated solution to preserve polymer integrity and performance.

🔬 Understanding Polymer Degradation: The Silent Threat

Polymers represent one of the most versatile material classes in manufacturing, pharmaceuticals, electronics, and countless other industries. Yet despite their widespread use, these materials face constant threats from environmental factors that gradually compromise their molecular structure. Temperature fluctuations, humidity variations, oxygen exposure, and ultraviolet radiation work synergistically to break down polymer chains, leading to catastrophic failures in critical applications.

The degradation process often begins at the molecular level, invisible to the naked eye. Free radicals form through oxidation reactions, initiating chain scission that progressively weakens the material. Hydrolysis attacks ester and amide bonds in the presence of moisture, while thermal stress accelerates these reactions exponentially. By the time visible signs appear—discoloration, brittleness, cracking, or dimensional changes—significant damage has already occurred.

Understanding these degradation mechanisms is essential for anyone working with polymer materials. Whether you’re storing raw materials, manufacturing polymer components, or maintaining finished products, environmental control isn’t optional—it’s fundamental to ensuring material performance and longevity.

💡 What Are Microclimate Enclosures?

Microclimate enclosures create controlled atmospheric environments around sensitive materials, isolating them from harmful external conditions. Unlike traditional storage methods that rely on building-wide climate control, these specialized systems generate localized environments tailored to specific material requirements. This targeted approach offers superior protection while reducing energy consumption and operational costs.

The core principle involves creating a sealed or semi-sealed environment where temperature, humidity, atmospheric composition, and light exposure can be precisely regulated. Modern microclimate systems incorporate sensors, automated controls, and data logging capabilities to maintain optimal conditions continuously. Some advanced units even feature predictive algorithms that anticipate environmental changes and adjust parameters proactively.

These enclosures range from small desktop chambers for laboratory samples to warehouse-sized installations protecting bulk polymer inventories. The scalability and flexibility of microclimate technology make it applicable across industries, from aerospace composites requiring ultra-dry conditions to medical polymers needing sterile, temperature-stable environments.

🌡️ Critical Environmental Factors Affecting Polymer Stability

Temperature Control: The Foundation of Polymer Preservation

Temperature stands as perhaps the most critical variable in polymer stability. Every polymer has a characteristic glass transition temperature (Tg) below which molecular chains have limited mobility. Operating above this threshold can lead to creep, dimensional instability, and accelerated aging. Conversely, extremely low temperatures may cause embrittlement in some formulations.

Thermal cycling—repeated heating and cooling—proves particularly damaging. These fluctuations create internal stresses as different polymer components expand and contract at varying rates. Over time, this mechanical fatigue manifests as microcracking, delamination in composites, and interfacial failures in multi-layer structures.

Microclimate enclosures address these challenges through precise thermal regulation. Advanced systems maintain temperature stability within ±0.5°C, eliminating the fluctuations that characterize conventional storage environments. This consistency dramatically extends polymer shelf life and maintains material properties within specification.

Humidity Management: Preventing Hydrolytic Degradation

Moisture represents another primary degradation vector for many polymer classes. Hygroscopic polymers like polyamides (nylons), polycarbonates, and polyurethanes readily absorb atmospheric water, leading to plasticization, dimensional changes, and hydrolytic chain scission. Even seemingly non-hygroscopic materials can suffer when moisture penetrates through surface defects or interfaces.

The relationship between relative humidity and polymer degradation follows complex kinetics. At low humidity levels (below 20% RH), most polymers remain stable. However, as humidity rises, absorption rates increase exponentially. Above 60% RH, many engineering thermoplastics begin showing measurable property degradation within weeks.

Sophisticated microclimate systems employ desiccant-based or condensing dehumidification technologies to maintain ultra-low humidity levels. Industrial applications often target humidity levels below 10% RH, with some specialized systems achieving conditions below 1% RH for highly moisture-sensitive materials like polyetheretherketone (PEEK) or liquid crystal polymers.

Atmospheric Composition: Beyond Oxygen Exclusion

Oxygen drives oxidative degradation in virtually all organic polymers. This reaction generates peroxy radicals that propagate through polymer chains, causing crosslinking in some materials and chain scission in others. Antioxidants added during compounding provide temporary protection, but their efficacy diminishes over time, especially in oxygen-rich environments.

Microclimate enclosures can create inert atmospheres using nitrogen, argon, or other non-reactive gases. This approach proves particularly valuable for reactive polymers like polyolefins, elastomers, and polymers containing unsaturated bonds. Some systems maintain oxygen concentrations below 100 ppm, effectively halting oxidative degradation even at elevated temperatures.

Beyond oxygen control, atmospheric management addresses other reactive species. Ozone, nitrogen oxides, and volatile organic compounds present in industrial environments can initiate or accelerate polymer degradation. Activated carbon filtration and chemical scrubbing systems integrated into microclimate enclosures remove these contaminants before they contact sensitive materials.

🏭 Industrial Applications and Case Studies

Pharmaceutical Industry: Ensuring Drug Delivery System Integrity

Modern pharmaceuticals increasingly rely on polymer-based drug delivery systems—hydrogels, microspheres, implantable devices, and controlled-release formulations. These systems must maintain precise degradation profiles to ensure correct dosing kinetics. Environmental variations during storage can alter degradation rates, compromising therapeutic efficacy and patient safety.

A major pharmaceutical manufacturer implemented microclimate storage for biodegradable polymer implants designed to release medication over six months. Prior to installation, ambient warehouse conditions caused batch-to-batch variability in release profiles, resulting in costly rejections. After implementing climate-controlled enclosures maintaining 15°C and 30% RH, variability decreased by 87%, and shelf life extended from 18 to 36 months.

Aerospace Composites: Protecting High-Performance Materials

Carbon fiber reinforced polymers and other advanced composites dominate modern aerospace construction due to their exceptional strength-to-weight ratios. However, these materials demand meticulous storage conditions. Matrix resins can absorb moisture, leading to reduced glass transition temperatures and compromised mechanical properties. Prepreg materials have limited out-time and require sub-zero storage to prevent premature curing.

Aerospace manufacturers utilize large-scale microclimate freezers maintaining temperatures between -18°C and -40°C with humidity below 5% RH. These systems protect millions of dollars in composite inventory while ensuring materials meet stringent certification requirements. Digital monitoring systems track every roll of prepreg, alerting technicians if environmental excursions occur and automatically updating remaining shelf life calculations.

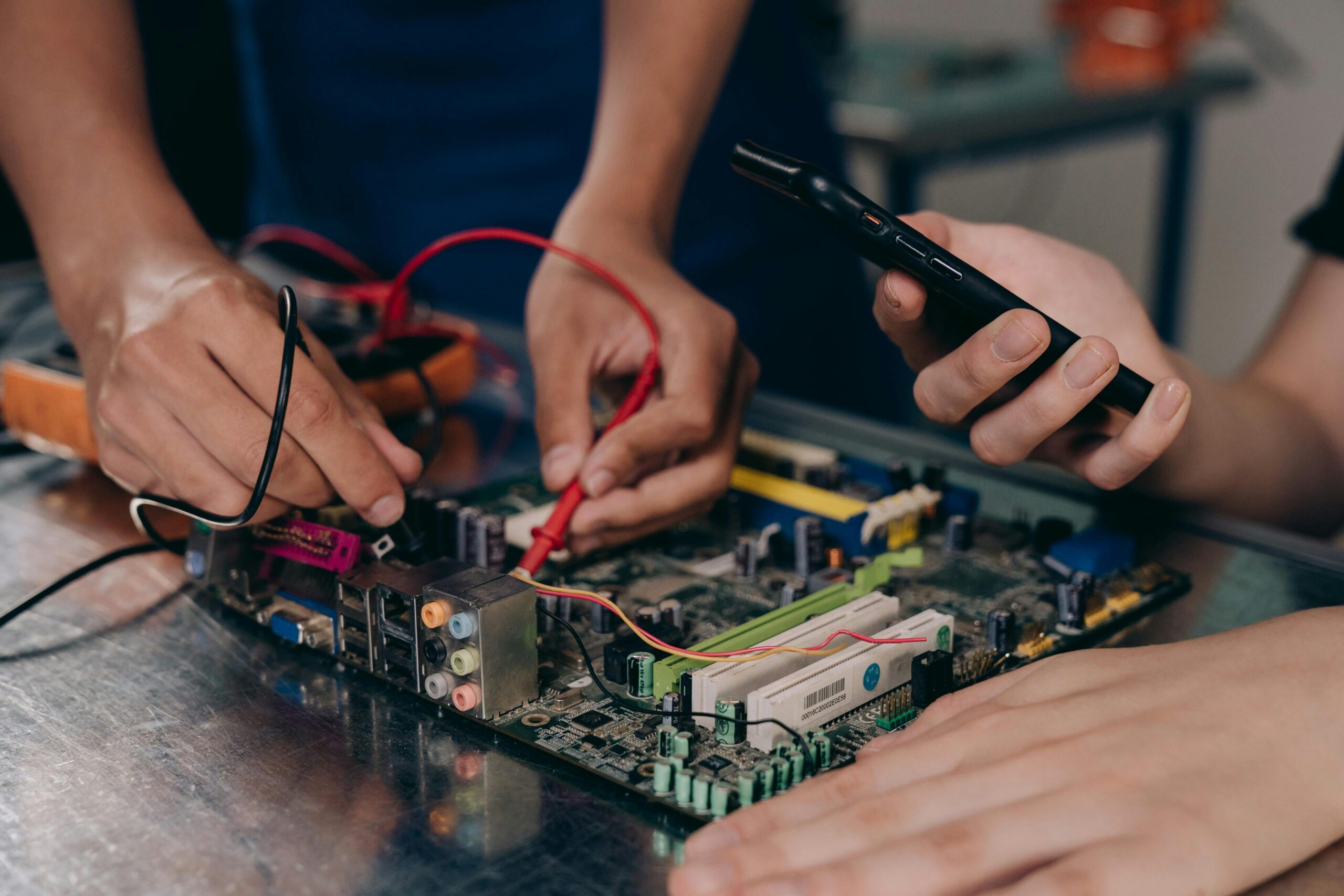

Electronics Manufacturing: Safeguarding Polymer Substrates and Encapsulants

Electronic components incorporate numerous polymers—printed circuit board substrates, encapsulants, conformal coatings, and flexible electronics materials. Moisture absorption by these polymers causes dimensional instability, reduced insulation resistance, and “popcorning” during soldering operations where trapped moisture vaporizes explosively.

Electronics manufacturers employ dry storage cabinets as compact microclimate solutions. These units maintain ultra-low humidity environments (typically 1-5% RH) using desiccant systems or nitrogen purging. Component traceability systems integrate with environmental monitoring, ensuring moisture-sensitive devices receive proper baking before assembly if storage time limits are exceeded.

🔧 Designing Effective Microclimate Systems

Matching Technology to Material Requirements

Effective microclimate design begins with comprehensive material characterization. Different polymers exhibit vastly different environmental sensitivities. A storage solution appropriate for polypropylene would prove inadequate for polyamide 6,6, which requires much stricter humidity control. Material safety datasheets and supplier specifications provide baseline requirements, but actual application conditions may demand tighter tolerances.

Consider these key factors when specifying microclimate systems:

- Temperature range and stability: Does the material require refrigeration, freezing, or simply stable ambient conditions?

- Humidity targets: What maximum relative humidity ensures material stability over the required storage duration?

- Atmospheric composition: Does oxygen exclusion provide significant benefits for this specific polymer?

- Light protection: Is the material susceptible to UV or visible light degradation?

- Throughput requirements: How frequently must materials enter and exit the controlled environment?

- Documentation needs: What level of environmental monitoring and data logging does quality assurance demand?

Monitoring and Validation Technologies

Modern microclimate enclosures incorporate sophisticated monitoring systems that continuously verify environmental parameters. Multi-point temperature and humidity sensors distributed throughout the storage volume detect thermal gradients and moisture pockets that might escape single-point monitoring. Data logging systems create comprehensive environmental histories, essential for regulatory compliance and failure investigations.

Validation protocols verify that microclimate systems maintain specified conditions under all operating scenarios. Empty-chamber testing establishes baseline performance, while loaded testing confirms that thermal mass and airflow patterns around stored materials don’t create uncontrolled microclimates. Door-opening tests verify recovery times, ensuring brief access doesn’t compromise protection.

Emerging technologies enhance monitoring capabilities further. Wireless sensor networks eliminate complex wiring while providing flexible sensor placement. Cloud-based monitoring platforms enable remote oversight and automated alerts. Some advanced systems incorporate machine learning algorithms that predict maintenance needs before failures occur, preventing costly environmental excursions.

💰 Cost-Benefit Analysis: Justifying the Investment

Implementing microclimate enclosures requires significant capital investment, particularly for large-scale installations. However, the costs of inadequate polymer protection often dwarf system expenses. Material rejection rates, premature failures, warranty claims, and reputational damage from defective products create substantial hidden costs that proper environmental control eliminates.

Consider a composite manufacturing facility storing $2 million in carbon fiber prepreg annually. Without proper climate control, material rejection rates of 5-10% are common, representing $100,000-$200,000 in annual losses. A microclimate freezer system costing $150,000 with $20,000 annual operating costs pays for itself within the first year while eliminating ongoing material losses.

Energy efficiency represents another significant consideration. Building-wide climate control to protect sensitive polymers requires conditioning entire facilities to stringent specifications—an expensive proposition. Microclimate enclosures concentrate environmental control where needed, dramatically reducing energy consumption. Facilities report energy cost reductions of 60-80% compared to whole-building approaches while achieving superior environmental control.

🌍 Sustainability Considerations in Polymer Protection

As industries embrace sustainability, polymer protection strategies must align with environmental goals. Microclimate enclosures contribute to sustainability through multiple mechanisms. By extending polymer shelf life and reducing rejection rates, these systems minimize material waste—a critical consideration given the environmental footprint of polymer production.

Energy-efficient microclimate designs incorporate heat recovery systems, variable-speed compressors, and advanced insulation materials. Some installations integrate renewable energy sources, with solar panels powering refrigeration systems during peak demand periods. The concentrated nature of microclimate control makes such integrations more practical than whole-facility renewable energy systems.

Properly protected polymers also support circular economy initiatives. Recycled polymers often exhibit greater environmental sensitivity than virgin materials due to prior processing history and potential contamination. Microclimate storage ensures recycled polymers maintain usable properties throughout their lifecycle, making recycling economically viable and environmentally beneficial.

🚀 Future Trends in Microclimate Technology

Microclimate technology continues evolving rapidly, driven by advancing sensor technologies, artificial intelligence, and materials science breakthroughs. Next-generation systems will feature predictive environmental control, where machine learning algorithms anticipate degradation risks based on material type, storage duration, and planned applications. These intelligent systems will automatically adjust conditions to optimize the balance between preservation and energy efficiency.

Integration with broader manufacturing execution systems represents another emerging trend. Microclimate enclosures will communicate directly with enterprise resource planning platforms, automatically updating material certifications, recalculating shelf life, and triggering reorder points based on actual storage conditions rather than conservative estimates.

Nanotechnology promises revolutionary improvements in both monitoring and control. Nanoscale sensors embedded within polymer matrices will detect degradation at molecular levels, providing early warning before properties deteriorate significantly. Meanwhile, advanced materials incorporating phase-change materials and aerogels will enable more compact, energy-efficient enclosure designs.

🎯 Implementing Your Polymer Protection Strategy

Developing an effective polymer protection program requires systematic planning and cross-functional collaboration. Begin by conducting a comprehensive audit of polymer materials, documenting environmental sensitivities, storage durations, and current rejection rates. This baseline assessment identifies high-priority applications where microclimate protection delivers maximum value.

Engage suppliers early in the specification process. Polymer manufacturers possess detailed knowledge of their products’ environmental requirements and can recommend specific storage parameters. Some suppliers offer materials pre-qualified for specific microclimate conditions, streamlining validation efforts.

Pilot programs provide valuable learning opportunities before full-scale implementation. Install smaller microclimate units for critical materials, document performance improvements, and refine operational procedures. These pilots generate compelling data for justifying larger investments while building organizational expertise in microclimate management.

Training programs ensure personnel understand proper system operation and the rationale behind strict environmental control. When operators recognize how environmental excursions compromise material properties, compliance with access protocols and monitoring procedures improves dramatically. Regular training updates maintain awareness as systems evolve and new materials enter production.

The protection of polymer materials through microclimate enclosures represents not merely a storage solution but a strategic investment in product quality, operational efficiency, and sustainability. As polymer applications become increasingly sophisticated and performance requirements more demanding, environmental control transitions from optional to essential. Organizations that implement comprehensive microclimate strategies position themselves for success in an industry where material integrity directly determines competitive advantage. The question is no longer whether to invest in polymer protection, but how quickly you can implement systems that safeguard your materials, your reputation, and your bottom line. 🛡️

Toni Santos is a preservation specialist and material conservator specializing in the restoration of botanical specimens, the stabilization of chemical fibers, and the structural analysis of degraded organic materials. Through an interdisciplinary and technically-focused approach, Toni investigates how natural and synthetic materials decay over time — and how to reverse, slow, and map these processes for cultural and scientific preservation. His work is grounded in a fascination with materials not only as physical substrates, but as carriers of environmental history. From botanical tissue restoration to fiber stabilization and decay structure mapping, Toni uncovers the chemical and biological pathways through which organic matter degrades and how intervention can preserve material integrity. With a background in conservation science and environmental material studies, Toni blends laboratory analysis with fieldwork to reveal how plants and fibers respond to environmental stressors, aging, and preservation strategies. As the creative mind behind qorvalyn, Toni curates preservation case studies, structural decay analyses, and conservation protocols that advance the technical understanding of material longevity, botanical integrity, and fiber resilience. His work is a tribute to: The recovery and stabilization of Botanical Material Restoration The chemical treatment of Chemical Fiber Preservation The mitigation strategies of Environmental Decay Reduction The diagnostic visualization of Preservation Structure Mapping Whether you're a conservation professional, material researcher, or steward of fragile collections, Toni invites you to explore the science of preservation — one fiber, one specimen, one intervention at a time.